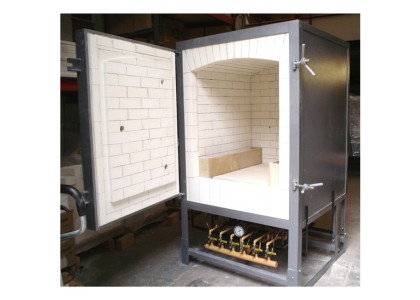

Gas Kilns

Enhance your ceramic firing capabilities with our selection of gas kilns. Our range includes Raku gas kilns and Thor gas kilns, available in various sizes to ensure efficient and uniform heat distribution. Perfect for professional and hobbyist potters alike. Browse our range today.

What Are the Advantages of Gas Kilns?

Gas kilns offer significant flexibility, allowing you to control the atmosphere within the kiln while firing. This control enables the creation of both oxidation and reduction atmospheres, offering glaze and surface effects that other firing methods can’t achieve. Many potters prefer gas kilns for their ability to produce unique finishes, such as the rich, unpredictable effects of reduction firing. Potters also like the unique experience of manually firing a gas kiln without assistance from a controller, which gives an immersive and rewarding result.

What Type of Fuel Do I Need for Gas Kilns?

Gas kilns typically operate on either propane or natural gas. Propane is ideal for locations without a natural gas supply, as it can be stored in tanks. Natural gas, supplied through the mains, is often preferred for larger kilns due to its continuous supply and lower cost. There is, however, usually a slightly greater equipment cost. Before purchasing a gas kiln, it’s therefore important to consider which fuel type is available and suitable for your workspace.

Temperature Capabilities of Gas Kilns

Gas kilns can reach temperatures of 1280°C to 1350°C, making them ideal for firing stoneware and porcelain. Some models are capable of even higher temperatures if needed. These high temperatures allow for durable and vitrified ceramics, ensuring fully matured clay bodies and glazes. Depending on the kiln design, temperature control may be adjusted manually or with digital controllers to achieve precise firing results. Always ensure proper ventilation when using the kiln to prevent gas buildup.

How Do I Maintain a Gas Kiln?

Regular maintenance is crucial for the optimal operation of a gas kiln. Using a vacuum cleaner, remove any dust or debris from the kiln shelves and interior. Inspect the kiln’s burners and gas pipes regularly for wear or damage. To ensure safe and efficient operation, get the kiln serviced once a year by a professional.

Why Choose Potclays?

With over 80 years of expertise, Potclays stands as a premier manufacturer of high-quality gas kilns, meticulously crafted in our Stoke-on-Trent workshop. Our range includes the specialised Raku and robust Thor models, each designed for optimal firing efficiency and uniformity.

Whether you're exploring experimental firings with a compact Raku kiln or scaling up production with a larger Thor model, we're here to provide expert guidance and support tailored to your requirements. For any enquiries regarding our gas kilns, do not hesitate to contact us.