Kilncare Ikon V46 Toploading Kiln 3.0kW

- Sku - 800-2V46

- In Stock

| Each (Exc. VAT) | Price (Exc. VAT) | Quantity | |

|---|---|---|---|

| 1.00 | £2,618.33 | £2,618.33 | |

| Each (Inc. VAT) | Price (Inc. VAT) | Quantity | |

| 1.00 | £3,142.00 | £3,142.00 |

Please type the quantity you require below or add pre-defined quantities using the controls above.

-

Description

Kilncare Ikon V46 Toploading Kiln 3.0kW

NEW IN 2022/23!

IKON Range - When average just isn’t good enough

Introducing the IKON. Built in the heart of The Potteries, the IKON has Ceramics running through its veins. The IKON has unbeatable performance, reliability and heritage and that is what makes it the PREMIUM kiln.

Distributed by Potclays worldwide.

IKON V46 Specification:-

- Internal size 416mm (Diameter) x 330mm (Height)

- External Size 725mm (wide) x 750mm (deep) x 775mm (High)

- Capacity 46Lts

- Weight 88kg

- Power 3KW

- Amps 12.6A

- Voltage 230v

- Maximum Temperature 1315c

- Controller included KCR32C (KCR32C WIFI optional)

- Provided with U.K. three pin plug top and 2m lead.

- V46 Furniture set available separately

IKON Range Features:-

- Ultra-efficient with an average 1280c stoneware firing using only 18 units of electricity.

- 1315c maximum temperature. (1200C on V61E)

- Triple section lid seal including anti draught rope seal, brick to brick and lid insert.

- Three layer chamber insulation including GX Micropore “super” insulation.

- Double layer floor insulation with full stainless steel under plate.

- Lower inlet port with shutter raised from the kiln floor to avoid debris blockage.

- Upper exhaust port with shaped chimney and multi position shutter.

- Lid and chamber made from 100% 304 brushed stainless steel.

- Strong skeleton sub frame to absorb lid lifting and closing pressure.

- Twin gas spring lid assist. One on either side to make lifting and closing an easy operation and avoid lid twist.

- Twin lid clamps. One of either side to keep even lid pressure when closed, with padlock locking facility.

- Kanthal A1 elements.

- Element connections housed separately from power components to ensure cool running.

- Low rear mounted and heavily ventilated power component box to keep the major components cool and away from residual heat generated by the chamber during firing.

- Solid State Relay control switching for maximum reliability due to no moving parts and also near silent operation.

- Dual contactor over fire protection circuit

- Dual channel lid safety cut off switch

- Dual contactor lid cut off circuit.

- KCR32C 32 program, 32 segment controller.

- KCR32C can be hand held to avoid kneeling by the kiln to set and program.

- Keypad lock, power used, over fire protection, program pause, segment advance and 4 day delay are all features of the KCR32C.

- Optional KCR32CWIFI internet access to kiln status and programs, real time monitoring from any device, anywhere with internet access via the Kilncare GATEway.

- Twin rear solid castors.

- Twin front swivel and lockable castors.

- 36 month guarantee on all parts excluding the elements.

- Built and designed by Kilncare in the U.K.

Optional at extra cost: Internet access to view real time status and access dataThe optional KCR32C WIFI allows the user to access the kiln in real time from anywhere with internet access via the Kilncare GATEway on our website. The benefits of this are obvious as there is no longer the need to travel to the studio or work place to see how the firing is proceeding or if indeed the firing is going as planned.

Also in the GATEway, which is unique to each user via password access, there is a firings library where past firings can be stored and named, a notes section and a log amongst other features.

Machined lid insert of three section seal

The IKON has a unique three section lid seal that massively improves heat retention. The first section is a machined insert in the brick lid that puts a brake on the heat before it reaches the second section, a traditional brick on brick contact which is what the majority of top loaders rely on as their only seal. Section three is an outer anti-draught rope lining around the outside of the chamber that traps in any remaining heat that makes it through the first two sections of the seal.

Strong skeleton sub frame

The IKON is ultra strong due to the skeleton sub frame that the chamber sits on. A common issue with top loaders is the pressure and movement that is generated as the lid is open and closed and ultimately this will add strains to the chamber that can cause damage. The skeleton sub frame effectively leaves the chamber free to sit there and simply do its planned job of heating the ware inside whilst the skeleton does all of the physical work.

Twin gas spring lid lifts

The lid of the IKON is lifted with a gas spring on either side so that the pressure of lifting the lid is even across it and so vastly reducing twist and cross pressure on the brickwork. As mentioned previously, this is helped by the skeleton sub frame. Twin gas springs ensure that the lid weight is counteracted to such a degree that even if the lid is accidentally knocked whilst in the vertical position, its decent will be controlled and not result in brickwork damage.

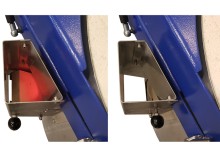

Chamber exhaust shutter

Whilst chamber exhausts are common place on top loaders, the IKON is unique as it has a shutter that can vary the effectiveness of the exhaust, which is also larger than most, as well as close it all together when the efficiency of the kiln is most needed. This increases the efficiency of the kiln as it retains its heat when it most needs it.

Kiln Furniture Set

Kiln Furniture SetThe optional kiln furniture set (order here) comprises of 2 shelves of 368mm, 3 props of 25mm, 3 props of 50mm, 3 props of 75mm and three props of 100mm.

Low level cool power panel

The electrical camponents of the kiln are mounted at the rear of the kiln at low level. The mounting panel is highly ventillated and there is also an air space between the panel and the kiln chamber. This ensures that the electrical components of the kiln are kept at minimum temperature which in turn vastly extends the life span of the components. Inside this panel is the Solid State Relay which enables the kiln to have optimum control and due to there being no moving components in the Solid State Relay, there is no wear so ensuring maximum reliablity. No moving parts also means that the kiln is near silent in operation apart from the traditional buzz of the elements.

Lockable swivel castors

The kiln sits on heavy duty castors. Two fixed wheel at the rear and two lockable and swivel castors at the front.

The controller for the kiln can be held remotely to make programming the kiln an easy and comfortable process.

The controller for the kiln can be held remotely to make programming the kiln an easy and comfortable process.

KCR32C Controller

- 32 programs - each with up to 32 segments

- Each segment is a controlled heating/cooling ramp soak

- Suitable for glass or ceramics use

- Soak times up to nearly 100 hours

- Ramp rates from 1 to 999°C/hour full

- Program Pause & Segment Advance facilities

- Keyboard lockable

- Delayed start facility - up to 4 days

- Power failure recovery

- Energy used display

- Event / Damper / Fan relay output

- Alarm relay with alarm buzzer

- Mains power switch

- Built in the United Kingdom

The KCR32C is multi-program controller designed for glass, ceramics & pottery use. It has a huge 32 programs each of up to 32 segments. Each segment is a controlled heating/cooling ramp followed by a soak. It is supplied pre-programmed with 9 typical glass programs and 9 typical ceramics programs (which can be over-written). The slow rate capability of the KCR32C, down to 1c per hour if required.

KCR32CWIFI Controller (Optional)

The KCR32CWIFi is internally the same as the KCR32C but has the capability to be accessed and controlled remotely from your mobile device. This is one of the most important advances in Kilncare kilns for many years. Using Kilncares GATEway access site you can view how your kiln is running in real time. Stop the firing or adjust programs all without even being in the same country let alone the same room. The KCR32WIFI is also fitted with a USB port that allows programs to be entered that way direct from PC if required and also allows us to apply updates and run diagnostics without travelling to your kiln.

-

Downloads

-

Delivery & Returns

Delivery & Returns

Full Delivery & Returns information at this link>

DELIVERIES

Current Delivery Times: Please check the latest update at this link>

Delivery Costs: Your carriage charge will be calculated at checkout based upon the volumetric weight of your order, and your location. If for any reason your delivery charge cannot be calculated at checkout, you will see a message explaining that our sales team will contact you with a quote. You will be under no obligation to accept this and have the right to cancel your order.

We deliver throughout the UK and overseas using a trusted third-party distribution network. Delivery is to kerbside or letterbox only.

Although carriers will endeavour to deliver within the agreed timeframe, unexpected delays due to weather conditions, breakdowns, traffic and other factors may cause some disruption to schedules.

IMPORTANT INFORMATION

We are bound by the terms and conditions of our carriers therefore we cannot pursue a claim if these instructions are not followed:-

Special Delivery Conditions: You must inform us at point of order of any special conditions such as restricted access or opening times, otherwise you will be liable for any consequential costs incurred.

Damage/Missing Items: You must check your delivery carefully before providing a ‘clear’ signature to the driver. Outward signs of damage/disruption to packaging must be noted alongside your signature. You must notify Potclays of damage or missing items within 24 hours of delivery.

RETURNS

Returned Goods (Non-faulty): Subject to our prior consent having been obtained, products can be returned to us in an unused condition within 30 days of invoice date. An administrative charge will be levied of 10% of the nett value plus transport, but subject to a minimum charge of £2.00.

Returned Goods (Faulty): If merchandise is returned because of some defect or due to error on our part, full credit/refund will be given. However, customers must contact us in advance so that making methods and user error can be ruled out.